10 Easy Facts About Motorcycle Parts New Zealand Specialists Shown

Table of Contents4 Simple Techniques For Motorcycle Parts New Zealand SpecialistsThe Single Strategy To Use For Motorcycle Parts New Zealand Specialists8 Simple Techniques For Motorcycle Parts New Zealand SpecialistsGetting The Motorcycle Parts New Zealand Specialists To WorkThe Basic Principles Of Motorcycle Parts New Zealand Specialists Things about Motorcycle Parts New Zealand SpecialistsFascination About Motorcycle Parts New Zealand SpecialistsThe Motorcycle Parts New Zealand Specialists Diaries

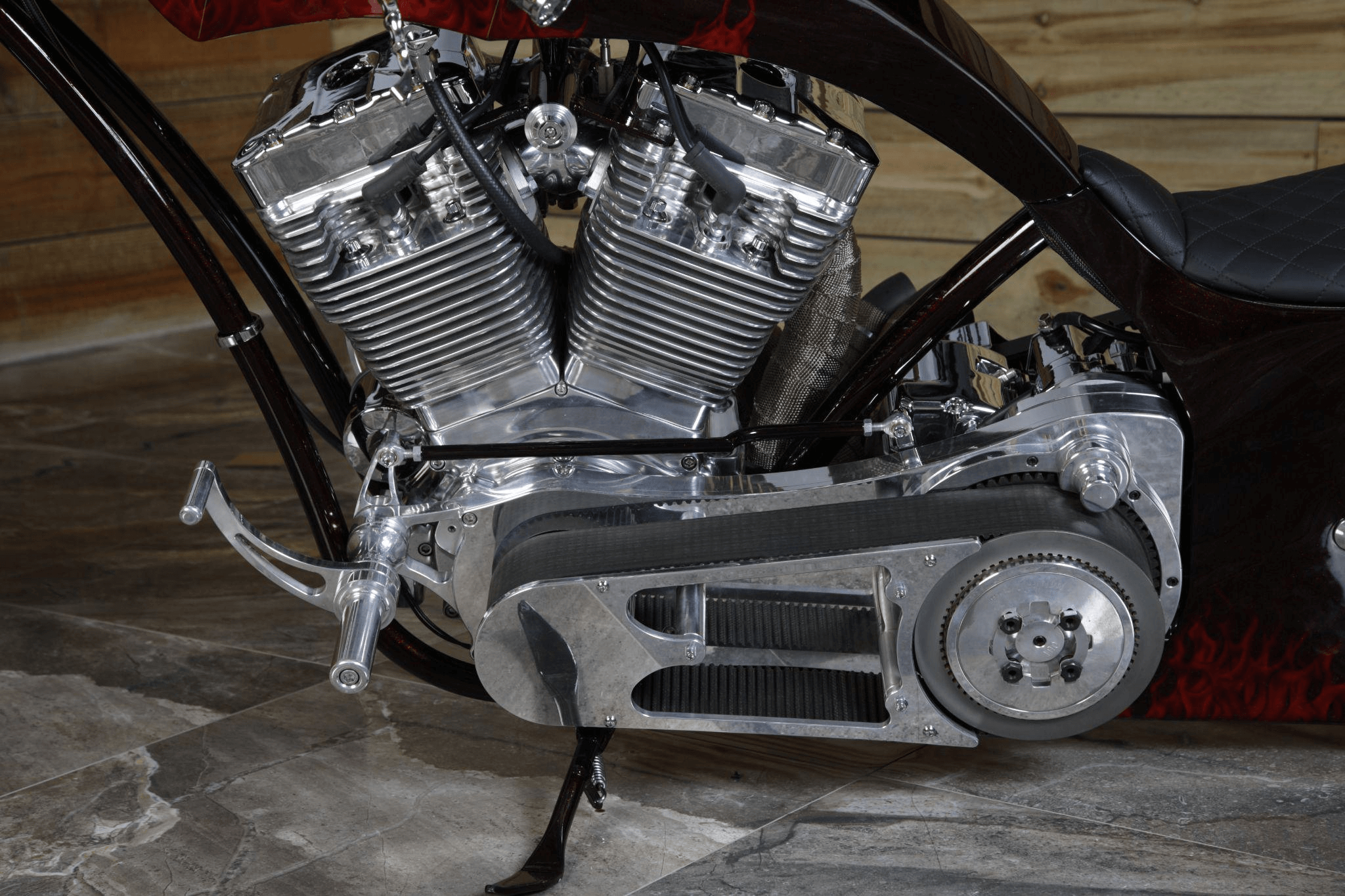

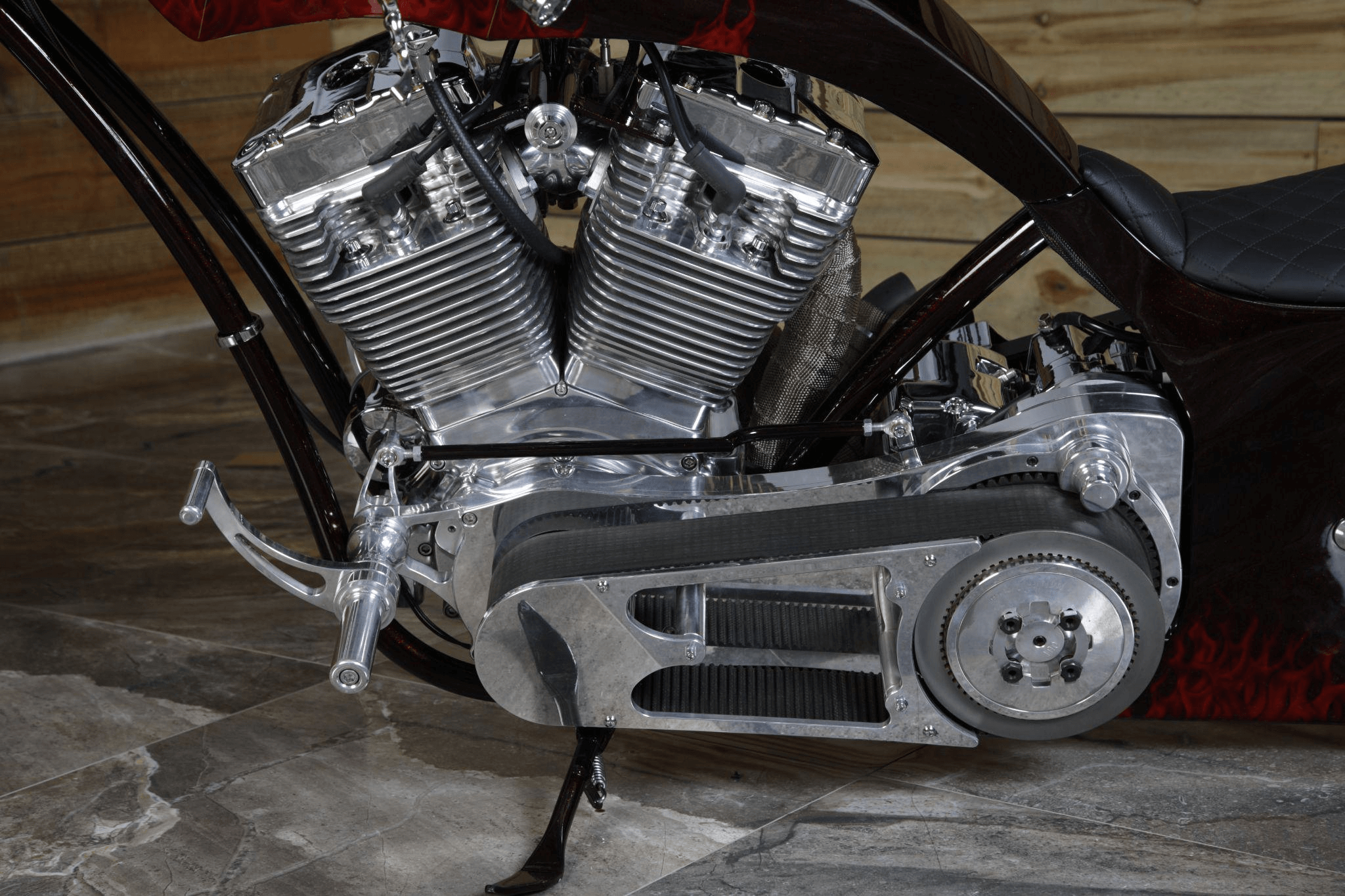

So, get to out to one of our professionals today.CNC machining innovation is rapidly becoming the centerpiece of several manufacturing procedures around the world as a direct outcome of its many advantages over other approaches. Additionally, the sectors that produce motorbikes have obtained on board with this pattern. The most cutting-edge companies are now establishing their engine elements and wheels making use of machining strategies originally established for motorcycle components.

On the other hand, the impacts of industry are the main emphasis of this article. Allow's obtain right right into it. You may be wondering why we utilize. It is not difficult to fathom the factors that brought about this result. Currently that we have your interest allow us describe the reasoning behind this modern-day development in the motorbike manufacturing industry.

The Single Strategy To Use For Motorcycle Parts New Zealand Specialists

Additionally, you have full control over the look of the components, even to the minute information. Sometimes, motorcyclists may make a decision to spruce up their experience by setting up aftermarket components or customizing the bike's makeover. As soon as again, computer system mathematical control (CNC) machining is one of the most functional technique. Upgrades may be of any kind of type and design you want.

Some Ideas on Motorcycle Parts New Zealand Specialists You Need To Know

CNC machining might be made use of to make nearly all of a motorcycle's steel and plastic components. To proceed, we'll discuss a number of machined components for motorbikes. In comparison to those on autos, wheels on bikes have a tendency to be more obvious. As a result, the bike's appearances might be improved with the ideal personalization of these wheels.

Milling procedures are utilized to acquire the preferred degree of wheel personalization. An additional aspect of the motorcycle that might be personalized is the tires.

An Unbiased View of Motorcycle Parts New Zealand Specialists

When it pertains to a car (or a motorbike), one of the most essential element is the engine. Several individuals mention it as the "heart" of the car. On the other hand, the camshaft, the cyndrical tube head, and the pistons tend to be elaborate and need styles with a high degree of precision.

Use just high-grade items, nevertheless, considering that these lights are important for the safety of motorcyclists and other chauffeurs or people on the road, particularly at night. Motorcycle fronts lights have three main components: the light bulb, or light Find Out More source, the lens, and the real estate.

Milling processes with a remarkable finish would result in the lenses having a reflective high quality that is similar to that of a mirror. The cover, on the other hand, is not composed of delicate materials; rather, it is built out of hard polymers that can be machined right into more intricate patterns.

Little Known Questions About Motorcycle Parts New Zealand Specialists.

They typically have sophisticated geometries with a wide range of minute information. Bike manufacturers commonly cast these parts, however just for the production of bespoke components. Nonetheless, CNC machining is the technique of selection when generating one-of-a-kind items. Machining on five axes in today's world is the means whereby any kind of design form may be understood.

Choose Runsom for your customized motorbike components! We have the capability to make difficult Get More Information and elegant components making your bike incomparable.

Below are a few instances of metals typically utilized in bike component machining. Light weight aluminum is the key product utilized by firms specializing in creating custom motorbike components to produce most of these components - Motorcycle Parts New Zealand Specialists.

Zinc refers to an additional steel that is very light in weight and has excellent machining high qualities as a result of its high mechanical toughness. This product may be formed right into practically any shape and preserves its dimensions well. Even mission-critical elements that require a high degree of precision may profit from their usage.

Motorcycle Parts New Zealand Specialists Fundamentals Explained

One more metal that sees heavy usage in the production of CNC-customized parts is magnesium. It is amongst the lightest metals that are now available and has exceptional machinability features and toughness compatible with its reduced weight. One of the drawbacks of magnesium is that its dirt might conveniently ignite.

Their her latest blog most usual use in generating various motorbike components is fasteners, such as screws and screws. Their low susceptibility to oxidation and deterioration makes them excellent for this usage.

Motorcycle Parts New Zealand Specialists for Dummies

It seems that CNC turning and milling are the fundamental processes. In addition, it requires keeping bars of product, most often plastic or steel, in setting and then turning a reducing device to remove sections of the product as the material is turned.

These methods are equally vital and produce parts with high accuracy and consistent top quality. They are respectively: grinding, laser cutting, and boring. The term "surface finish" refers to post-processes after the preliminary machining stage. Motorcycle Parts New Zealand Specialists. The procedures aid boost the overall top quality of the machined bike elements. Below are the brief intro, advantages and disadvantages of five surface area treatment methods.

Some Ideas on Motorcycle Parts New Zealand Specialists You Need To Know